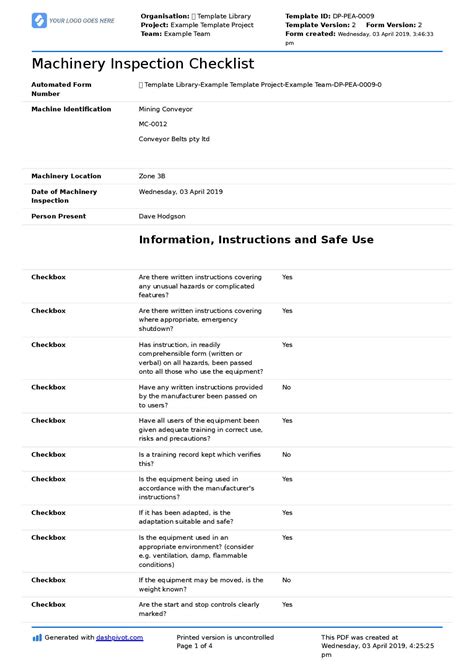

bending machine inspection checklist|machine safety inspection checklist : manufacturing Ensure the safety of your workplace with our comprehensive Machine Safety Inspection Checklist. This free PDF template covers all critical aspects of machine safety, empowering maintenance personnel and safety officers to .

The latest tweets from @fotyvaltv

{plog:ftitle_list}

31 de out. de 2016 · Avie: Halloween Style. Avie needs your help to create some stylish looks for Halloween. Use your imagination and good taste in fashion, make some beauty treatments and choose a really lovely Halloween costume for her. What people usually do on Halloween?

machine safety inspection checklist

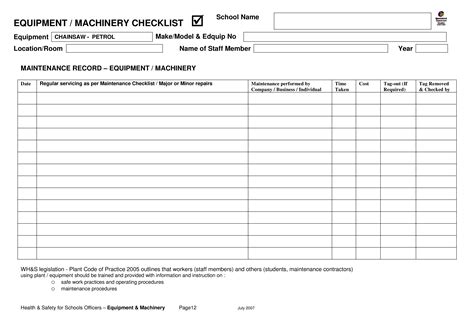

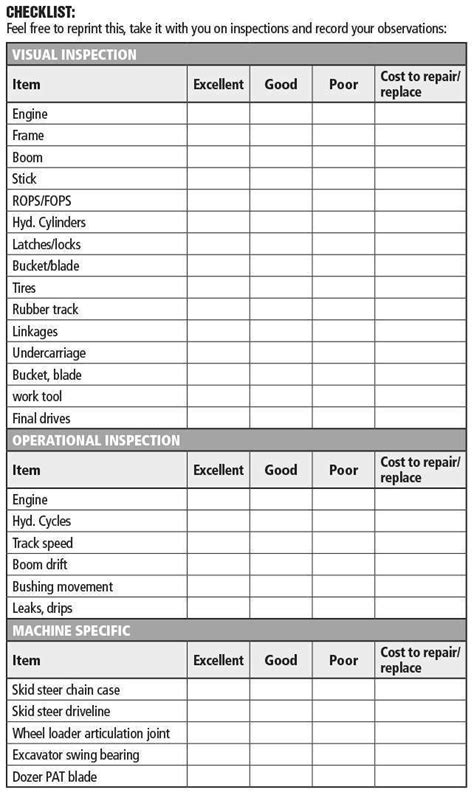

The document is an inspection checklist for a bending machine. It lists inspection points to check the condition and safety of the machine on a monthly basis. Items to check include guards, safety devices, lubrication, electrical connections, operating instructions, operator training, and .The document is a weekly checklist for inspecting a bending machine. It .This document provides a daily and weekly predictive checklist for a tube bending .Here is Safety Inspection Checklist of Bar Bending Machine which is required before using it to prevent accident. Get pdf on single click.

The document is a weekly checklist for inspecting a bending machine. It contains items to check such as fluid levels, guards, lubrication, and .Ensure the safety of your workplace with our comprehensive Machine Safety Inspection Checklist. This free PDF template covers all critical aspects of machine safety, empowering maintenance personnel and safety officers to . Before commencing work with a bar bending machine, a thorough inspection of the equipment and its surroundings is imperative. Equally important is the use of appropriate safety gear, including gloves, goggles, and helmets, .

This document provides a daily and weekly predictive checklist for a tube bending machine. The daily checklist includes 8 items to check such as cleaning the machine, checking oil levels, pressures, and leaks.1 Bar Bending Machine should be physically sound and in good condition. 2 Power cable should be free from damages. 3 All switches should be free from damage and in working condition.First and foremost, always wear appropriate and complete Personal Protective Equipment (PPE) before approaching and operating bending equipment. This includes, but is not limited to, safety goggles, safety gloves, and work boots to . The plate bending process involves using lubricants, residue post-rolling, and cut-down or broken parts of the steel plate that you would have rolled earlier. . Turn off the plate rolling machine before the inspection. Inspect the machine and look for the residue from the previous shift or day.

Sheet Bending Machine Maintenance Checklist: A Comprehensive Guide Sheet bending machines are essential equipment in various industries, including automotive, construction, and manufacturing. To ensure optimal performance, regular maintenance is crucial. A well-maintained sheet bending machine will not only increase efficiency and productivity .Bar Bending Machine का Regular Inspection और रखरखाव उनके प्रदर्शन, सुरक्षा और लंबे समय तक चलने के लिए महत्वपूर्ण है। नीच दी गई Bar Bending Machine Inspection Checklist का पालन करके, आप .Bar Bending Checklist - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. The document is a checklist for inspecting a bar cutting machine. It lists 9 items to check, including proper wiring, hoses, wheels, belts, bolts and nuts, noises, and debris. Technicians use the checklist to inspect the machine and ensure it is safe and functioning .

To help you make sure your inspection is as thorough as possible, we’ve put together a Plate Roll Inspection Checklist for you to use when assessing a used plate roll machine. In this checklist, you’ll find a list of key inspection points—with room to take notes so you can compare used machines later. Download the checklist now by filling . Figure 1: Front-end information collection and inspection as part of a die preventive maintenance (PM) program keeps the presses running and the metal forming operations much more productive. Editor’s Note: This is the first part of a two-part excerpt from Die Tooling: Preventive Maintenance for the Sheet Metal Stamping Industry.

The following points you must know while inspection of Steel Bar Bending machine. 1) Need To check Machine clearly identified & numbered OR No, 2) Need To check Machine Erected on a firm base OR No, 3) Need To check Machine grouted properly/Base wheel stopper provided OR No,

Equipment Safety Checklist – Bar Bending Machine $ 4.99 Check if your bar bending machine is excellent and safe to use with this easy-to-use safety checklist for bar bending machines.

Conclusion . The checklist plays a critical role in maintaining the bar cutting machines proper functioning, safety, and efficiency.By following the checklist diligently, operators and maintenance personnel can regularly conduct inspections and perform necessary maintenance tasks, thereby ensuring that the machine remains in an optimal condition.

The document is an equipment inspection checklist for a bar cutting machine. It contains 8 items to check such as the physical condition of the body, motor, guards, grounding, and operation by a competent person. Inspectors are to check each item and note Yes, No, or N/A in the given box and provide any remarks. Upon completion, the inspector marks the machine .This document provides a daily and weekly predictive checklist for a tube bending machine. The daily checklist includes 8 items to check such as cleaning the machine, checking oil levels, pressures, and leaks. The weekly checklist includes 11 items such as recording hydraulic oil temperature, checking the oil cooler, lubrication oil levels, and electrical and sensor . To prepare a checklist for the Steel Bar Cutting Machine inspection checklist, the following are some main points:. The physical condition of the body should be good & sound. The junction box or motor should be fully packed. The rotating part of the machine should be covered by a fixed guard. Before commencing work with a bar bending machine, a thorough inspection of the equipment and its surroundings is imperative. Equally important is the use of appropriate safety gear, including gloves, goggles, and helmets, to minimize potential injuries. . Restaurant Safety Checklist. FAQs. Why are safety procedures crucial when operating bar .

Machine Shop Self Inspection Checklist. Machine Shop Training Record. OSHA - Hand and Power Tools. OSHA - Machine Guarding . Power Roll Forming and Bending Machine. OSHA Machine Shop Guidance: Radial-arm Saw. OSHA Machine Shop Guidance: Sanders . If machine safety guards are removed due to maintenance ensure that Lockout/Tagout (LOTO .

machine maintenance checklist

5. Press the foot switch to start bending. The bending machine is different from the shearing machine. You can release it at any time. When you release the foot bending machine, it will stop and continue to descend. .6 Bar support should be fitted properly with machine. 7 Pin should be tightened properly. 8 Machine should be grounded properly. 9 Paddle should be in good condition and working properly. 10 Operator should be competent and authorised. Inspection Done By: Name: Department: Designation: Signature: Date: Fit for use: Yes/No Inspection Done By: Name:

Is your hydraulic press brake causing more headaches than it should? Ensuring these complex machines run smoothly is vital to avoid costly downtime and repairs. This article covers essential maintenance steps for . In this video we discussed about :Bar Bending Machine Inspection ~~~~~Why don't CO2 fire ext. If your machine is equipped with a cooling unit, have the unit drained and refilled; Have the leveling of your machine checked and adjust if necessary; Have all way wipers inspected for any damage – clean and replace any wipers that are damaged; Once a Year or Every 2000 Hours. Contact your local distributor and have the following inspected:Checklist for Equipment Inspection . Equipment Name & Number: 11-BAR BENDING MACHINE & Note: Please write Yes or No in the given box and if some comments write in remarks column. SN. Description Yes/No Remarks 1. Physical condition of body should be good & sound. # 2. #Electrical connection should be taken through

Pictorial view of Bar cutting machine for inspection checklist: Bar cutting machine is widely used in construction industry to cut steel or iron bars. It makes task easy as it is very tough job to cut bars due to its thickness. Company Name : Date of Inspection : Make :What is a Racking Inspection Checklist? A racking inspection checklist form is a tool used by internal staff as well as by certified auditors to assess the potential safety risks in warehouse storage racks. The pallet racking checklist template helps cover all the elements of the racks, such as beams, frames, and braces, and determine the level of risks using traffic light systems.• Modifications to the equipment without prior, written permission from BendPak Inc. • Injury or death caused by modifying, disabling, overriding, or removing safety features. • Damage to the equipment from external influences. • Incorrect operation of the equipment.

SN: Details: 1: Welding machine should be physically sound and in working condition. 2: Switches should be free from damage and properly insulated. 3: Welding and return led connection should be properly tight by means of socket/lugs.The document is an equipment inspection checklist for a gas cutting cylinders set. It contains 15 items to check such as ensuring the cylinder is kept upright and secured in a trolley, the regulator and pressure gauge are in good condition, and proper personal protective equipment is used. Workers must also have a fire extinguisher available and carry out the work in a fire . The main categories of the tube bending machines. Before going into detail about the tube bending machine selection process, let’s review the types of tube bending machines. We can divide them in three main categories: Manual tube bending machines are normally used for bending tubes with small diameter and lower wall thickness. These are used .

qbd 1200 laboratory toc analyzer

web1 dia atrás · Enem 2023; Gabarito Enem 2023. Voltar . 29/02/2024 07h27 Atualizado 29/02/2024 . Facebook; Twitter; . Houve seis votos pela contratação de um head hunter para entregar ao colegiado uma lista .

bending machine inspection checklist|machine safety inspection checklist